What are the specific applications of the QM30VT3 sensors in predictive maintenance?

The QM30VT3 three-axis vibration sensors have several specific applications in predictive maintenance:

Early Detection of Mechanical Issues:

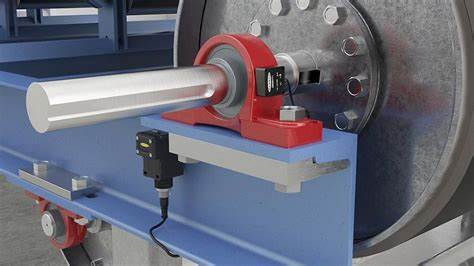

By continuously monitoring vibrations along three axes (X, Y, and Z), the QM30VT3 sensors can detect early signs of mechanical issues such as imbalance, misalignment, and bearing wear in rotating machinery. This early detection allows maintenance teams to address potential problems before they escalate into costly breakdowns.

Condition Monitoring of Critical Equipment:

The sensors are ideal for condition monitoring of critical industrial equipment, including motors, pumps, compressors, and turbines. By providing real-time vibration data, they enable maintenance teams to assess the health of these assets and make informed decisions about maintenance schedules and repairs.

Optimizing Maintenance Schedules:

With the high-resolution data acquired by the QM30VT3 sensors, maintenance teams can optimize their maintenance schedules based on the actual condition of the equipment rather than relying on fixed time intervals. This approach, known as condition-based maintenance, reduces unnecessary maintenance activities and lowers overall maintenance costs.

Reducing Unplanned Downtime:

By providing early warnings of potential machinery failures, the QM30VT3 sensors help minimize unplanned downtime. This is crucial for industries where downtime can result in significant production losses and revenue impacts.

Extending Equipment Lifespan:

Regular monitoring and timely maintenance interventions based on QM30VT3 sensor data can extend the lifespan of industrial equipment. By addressing wear and tear before it leads to catastrophic failures, the sensors contribute to the longevity and reliability of machinery.

Enhancing Worker Safety:

Predictive maintenance enabled by the QM30VT3 sensors also enhances worker safety by reducing the risk of unexpected machinery failures that could lead to accidents or injuries. By ensuring that equipment is in good working condition, the sensors contribute to a safer work environment.

Supporting Data-Driven Decision Making:

The data collected by the QM30VT3 sensors can be integrated into larger industrial IoT (IIoT) systems, providing maintenance teams with valuable insights into the performance of their equipment. This data-driven approach supports more informed decision-making and continuous improvement in maintenance practices.