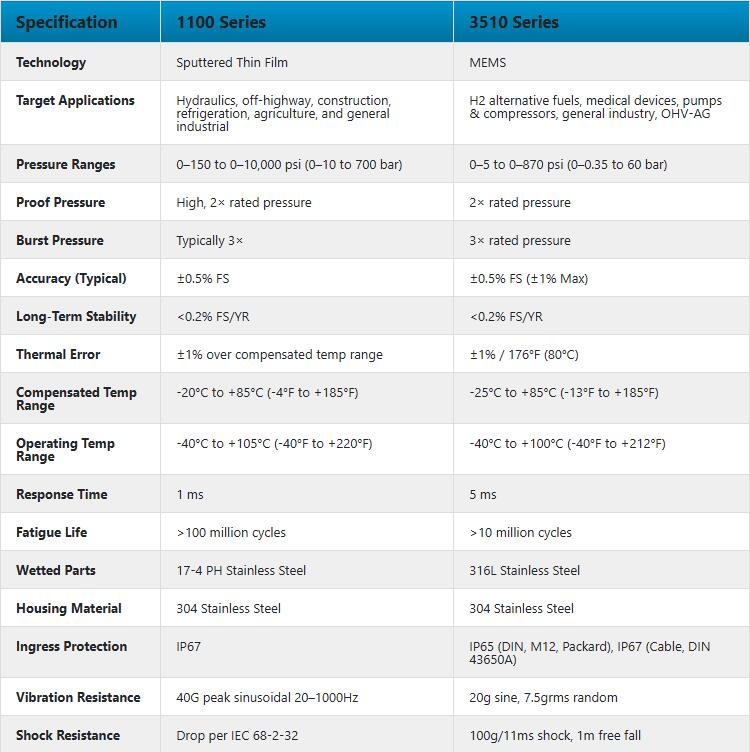

Comparative Analysis of GEMS 1100 Series and 3510 Series Pressure Sensors: How to Select?

Choosing the Right Sensor for Industrial Applications

In the realm of industrial pressure measurement, GEMS Sensors offers two prominent series—1100 and 3510—each tailored to distinct operational needs. This analysis explores their technical specifications, application domains, and performance traits to guide users in selecting the optimal solution.

1. Design & Material Construction

1100 Series:

Construction: All-stainless-steel wetted parts with a hermetic seal design.

Key Features: High-pressure resistance, compact form factor, and cost-effectiveness.

Ideal For: Price-sensitive applications requiring durability in standard industrial environments.

3510 Series:

Construction: 316L stainless steel wetted parts with MEMS (Micro-Electro-Mechanical Systems) technology.

Key Features: Lightweight, corrosion-resistant, and optimized for OEM integration.

Ideal For: Low-pressure applications demanding high precision and compactness.

Comparison:

The 1100 series prioritizes robustness for general-purpose use, while the 3510 series leverages advanced MEMS technology for lightweight, high-performance scenarios.

2. Pressure Range & Measurement Types

1100 Series:

Range: 0–150 psi to 0–10,000 psi (0–10 bar to 0–700 bar).

Types: Gauge pressure (relative to atmospheric pressure).

3510 Series:

Range: -1 to 40 bar (supports vacuum and positive pressure).

Types: Gauge, absolute, and compound pressure (measures vacuum and positive pressure in a single device).

Comparison:

The 1100 series excels in high-pressure environments, whereas the 3510 series offers versatility for low-pressure systems requiring multi-mode measurement (e.g., HVAC, refrigeration).

3. Accuracy & Stability

1100 Series:

Accuracy: ±0.25% FS (Full Scale) under optimal conditions.

Stability: Long-term drift of ≤0.5% FS/year.

3510 Series:

Accuracy: ±0.5% FS typical (±1% FS max).

Stability: Temperature drift ≤±1.5% FS across -20°C to 85°C.

Comparison:

The 1100 series provides higher baseline accuracy, making it suitable for precision-critical processes. The 3510 series balances accuracy with robust environmental adaptation, ideal for fluctuating conditions.

4. Environmental & Mechanical Resilience

1100 Series:

IP Rating: Not explicitly stated, but stainless-steel construction suggests resistance to moisture and chemicals.

Applications: Industrial machinery, refrigeration, and hydraulic systems.

3510 Series:

IP Rating: IP67/IP65 (dust-tight and water-resistant).

Resilience: Withstands vibrations up to 20g (25Hz–2kHz) and shocks of 100g/11ms.

Applications: Mobile equipment (agriculture, construction), chemical processing, and HVAC.

Comparison:

The 3510 series is engineered for harsh, dynamic environments, while the 1100 series suits stable industrial settings.

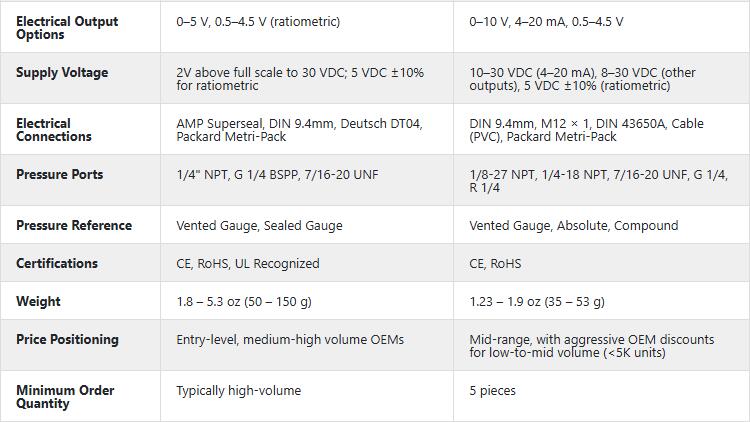

5. Electrical & Output Options

1100 Series:

Outputs: Voltage (0–5V, 0–10V) and current (4–20mA).

Compatibility: Standard industrial control systems.

3510 Series:

Outputs: 4–20mA, 0–10V, 0–5V, and 0.5–4.5V ratio metric.

Connectivity: M12, Mini DIN, and Packard MetriPack connectors for flexible integration.

Comparison:

Both series offer versatile outputs, but the 3510 series provides additional connector options for OEM customization.

6. Typical Applications

1100 Series:

Industrial machinery monitoring.

Refrigeration systems.

Hydraulic pressure control.

3510 Series:

Air compressors and pneumatic systems.

Chemical fluid transport (corrosive media).

HVAC water pressure and airflow management.

Refrigeration cycle monitoring.

Key Differentiator:

The 3510 series’ compound pressure capability makes it indispensable for systems requiring vacuum and positive pressure tracking, such as refrigeration and aeration controls.

Conclusion: Which Series to Choose?

Opt for the 1100 Series if:

High-pressure measurement (up to 700 bar) is critical.

Cost efficiency and simplicity are prioritized.

Applications involve stable environments (e.g., stationary machinery).

Opt for the 3510 Series if:

Low-pressure, multi-mode measurement (vacuum/positive pressure) is required.

The sensor must endure vibrations, shocks, or IP67 conditions.

Flexibility in outputs and connectors is needed for OEM projects.

GEMS’ 1100 and 3510 series cater to distinct industrial niches. By aligning technical requirements with environmental demands, users can maximize efficiency and reliability in their pressure measurement systems.