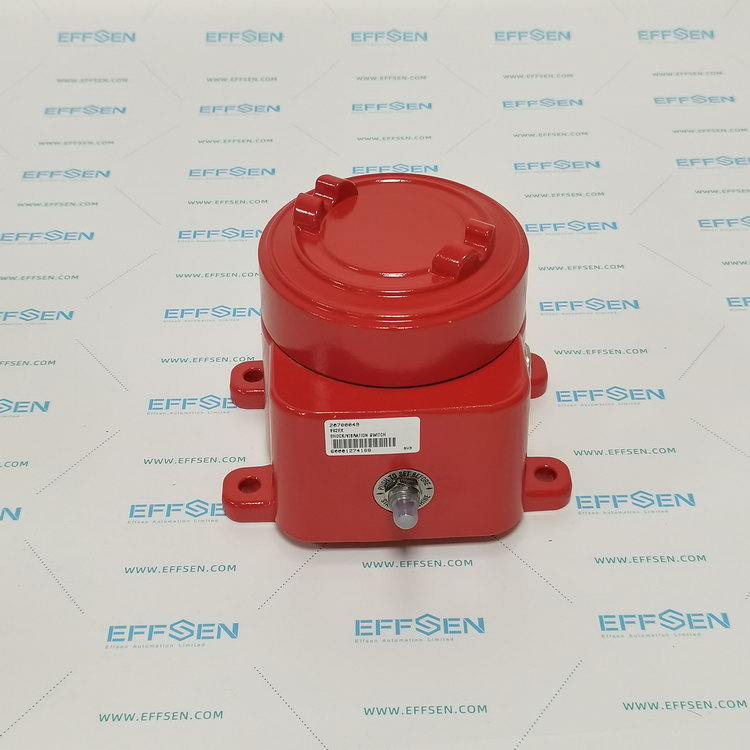

GEMS FS-380 Flow Switch

Product Overview

GEMS FS-380 series is a high-pressure online piston flow switch designed for industrial high-pressure pipelines, suitable for semiconductor cooling, industrial cleaning equipment, water treatment systems and other scenarios. Its core features include anti-clogging design, fixed flow setting and high-pressure resistance, which can meet the flow monitoring needs under complex working conditions.

Technical parameters

Flow range: 0.15-2.00 GPM (0.568-7.58 L/min)

Interface type: 3/8" NPT male thread or 1/2" NPT male thread

Material: Brass or 316 stainless steel (corrosion-resistant, suitable for a variety of media)

Working pressure: 1500 PSI (1056 mH₂O)

Temperature range: -20℉~275℉ (-28.8℃~+135℃)

Switch type: SPST normally open, 20VA load capacity

Filter: 100 micron filtration, reducing the risk of clogging

Core advantages

Anti-clogging design: integrated magnetic PPS piston structure, suitable for fluids containing particles or impurities.

High-pressure compatibility: Withstands 1500 PSI high pressure, suitable for industrial cleaning, lubrication systems and other scenarios.

High reliability: Fixed flow setting, simplified installation and debugging, ensuring long-term stable operation.

Wide applicability: Supports liquid, gas and some slurry media, adapting to various industry needs.

Typical application scenarios

Electronic equipment: laser head, welding machine, semiconductor cooling system.

Mechanical field: press, machine tool, robot lubrication system.

Water treatment and processing: pure water filtration, beverage packaging, gas sampling.