INOXPA SLR 33-80 Rotor pump

Product Overview

INOXPA SLR 33-80 is a hygienic rotary pump designed for applications requiring high hygiene standards and gentle fluid handling. It is widely used in the food, beverage, pharmaceutical and cosmetic industries.

Technical Specifications and Features

1. Materials and Surface Treatment

Product contact parts: Made of AISI 316L stainless steel (1.4404), in line with food grade requirements.

Non-product contact parts: Made of AISI 304 stainless steel (1.4301).

Seals: Product contact seals are made of EPDM (ethylene propylene diene monomer rubber) in accordance with FDA and EC 1935/2004 standards.

Surface treatment: Internal surface finish Ra ≤ 0.8 μm, external polishing to ensure cleanliness without dead corners.

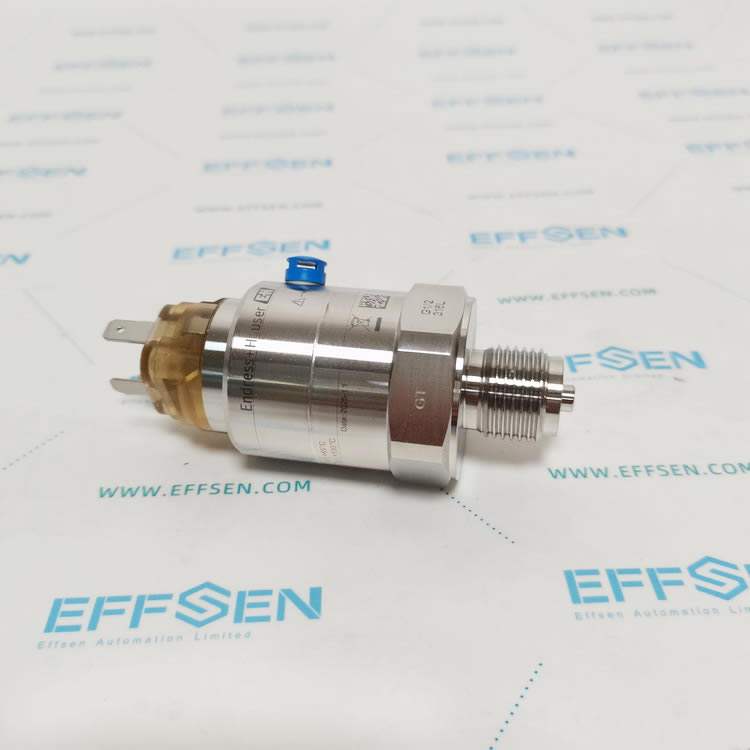

Mechanical seal

Type: Hygienic mechanical seal, single end face design (double end face seal can be selected according to requirements).

Sealing material: The rotating part is silicon carbide (SiC), the stationary part is carbon (C), and the gasket is EPDM to ensure corrosion resistance and sealing.

2. Performance parameters

Flow range: The specific flow rate needs to be determined according to the actual application and configuration, and is generally suitable for medium flow requirements.

Pressure and temperature: The design pressure and temperature range needs to refer to the technical manual of the specific model, but it is generally suitable for mild to medium pressure and temperature conditions.

Speed: It can be adjusted according to application requirements to ensure the gentleness of fluid handling.

3. Hygienic design

CIP/SIP compatibility: The pump body design meets CIP (online cleaning) and SIP (online sterilization) requirements for easy cleaning and disinfection.

No dead angle design: Reduce fluid residue and reduce the risk of cross contamination