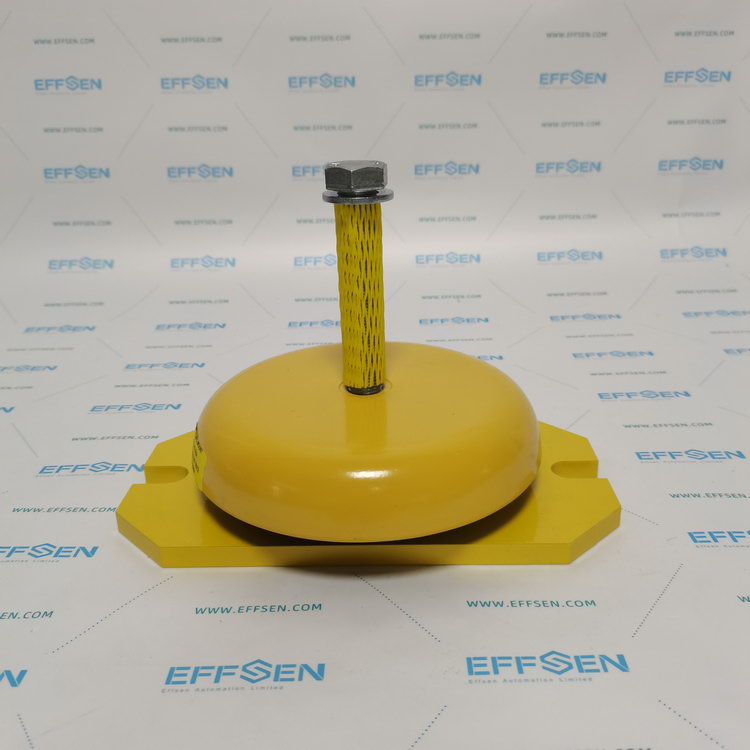

Bimba FS-3110-M1 Cylinder

It is a single-acting, spring return compact pneumatic cylinder, which belongs to the Flat-S™ series of Bimba (now a brand of IMI Precision Engineering). This series is known for its flat design, lightweight structure and high cost performance, and is suitable for industrial automation applications that require unidirectional thrust and automatic reset.

Main features

Single-acting design (Spring Return)

Compressed air drives the piston to extend, and the built-in spring provides the reset force (retract).

Suitable for scenarios where unidirectional pushing or quick return is required (such as clamping, lifting).

Ultra-thin and compact structure (Flat-S™ series)

Flat design (low profile), space saving, suitable for installation in restricted environments.

High-performance materials

Cylinder body: anodized aluminum alloy, lightweight and corrosion-resistant.

Piston rod: hard chrome-plated stainless steel, wear-resistant and rust-resistant.

Seals: polyurethane (PU) or nitrile rubber (NBR), compatible with most industrial air sources.

Modular mounting options

M1 suffix: usually indicates front thread mounting (other options such as flange and foot are available).

Standard parameters (subject to actual model)

Bore: estimated to be 3/8 inch

Stroke: 10 mm ("3110" may indicate stroke code).

Operating pressure: 50–120 psi (3.4–8.3 bar).

Spring return force: typical values are 5–20 N, depending on the model.

Typical applications

Automation equipment: small fixtures, valve triggering, positioning baffles

Packaging machinery: lightweight pushers, sealing devices

Electronic assembly: PCB board pressing, component sorting

Medical equipment: sterilization chamber door control, liquid distribution