Brand and Model: Germany's RICKMEIER (Rickmeier) R25/20 FL-M-G1-R-SO.

Product Type: Rotary positive displacement gear pump.

Core Design:

Precision Gear Structure: The gears are manufactured from high-quality carburized steel, subjected to heat treatment and precision machining to ensure wear resistance and long-term stability.

Compact Housing: Made of gray cast iron (EN-GJL), it features a lightweight structure that saves installation space.

Sealing Technology: Radial shaft seals (standard configuration), with the option of slip ring seals, effectively preventing leaks and contamination.

High Performance and Reliability:

Utilizes composite material sliding bearings (with special coating) that offer dry running tolerance, extending service life.

Short and straight fluid passages combined with a special tooth profile design achieve low-noise operation and excellent suction performance.

Media Adaptability:

Applicable Media: Lubricating liquids such as hydraulic oil, gear oil, fuel oil, waste oil, ATF oil, diesel emulsion, cutting oil, etc. (must be free of hard particles).

Temperature and Viscosity: Supports high-viscosity media (such as heavy oil, hot oil) and maintains efficient transfer in low-temperature environments.

Drive and Connection:

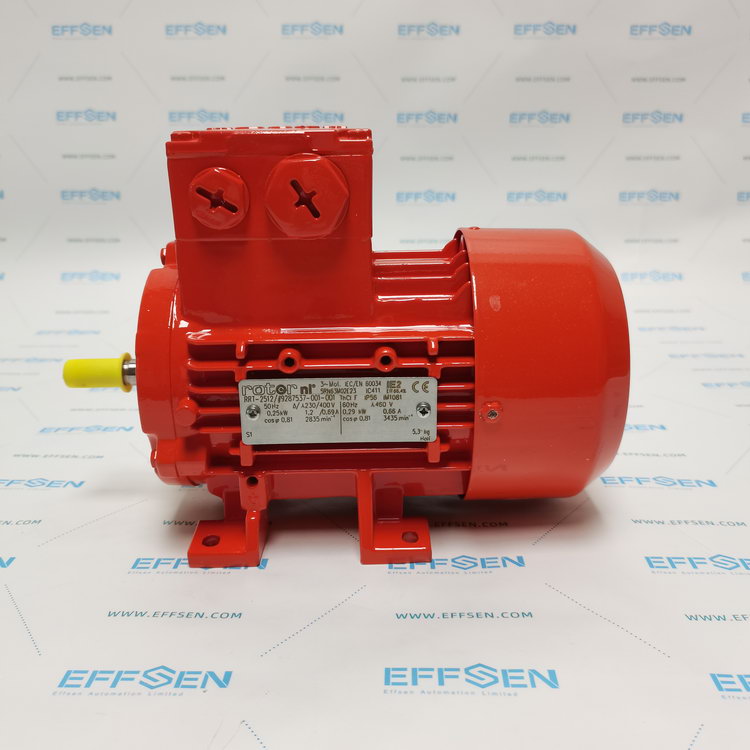

Standard configuration includes a three-phase asynchronous motor, with options for single-phase AC or DC motors to accommodate different voltage requirements.

Interface Type: G1 flange connection (pressure side), facilitating easy integration into hydraulic or lubrication systems.

Safety Precautions:

It is prohibited to install a check valve in the suction line to avoid air exhaust failures.

The medium must be clean and non-corrosive to prevent damage to the gears from hard particles.