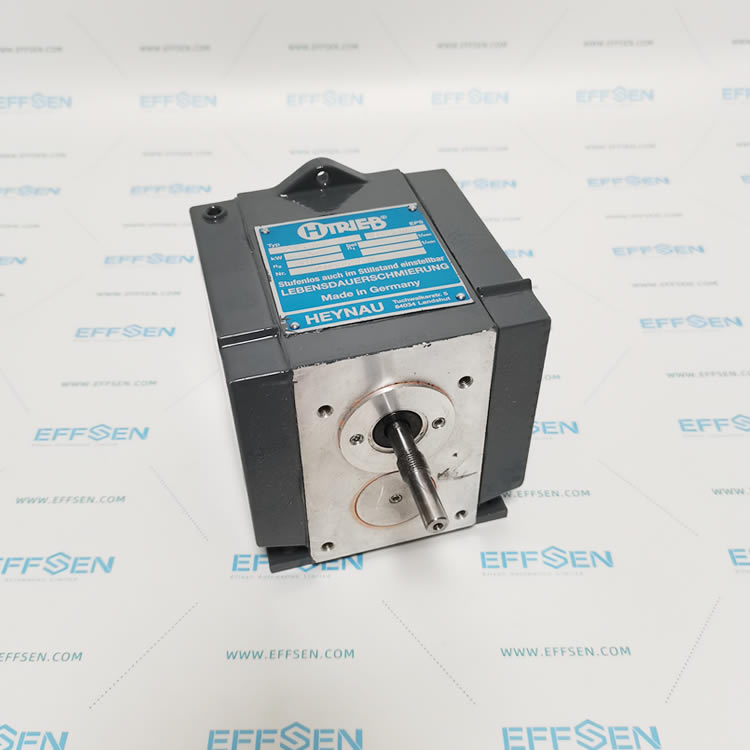

Product Code: 455525

Installation Specifications

The motor and pump must be connected via a flexible coupling, with a coaxiality error of less than 0.1 mm and an inclination angle of no more than 1°.

Inlet/outlet pipelines must be clean and free of impurities to prevent blockages or bearing wear.

Operational Control

Before Startup:

The pump chamber must be pre-filled with oil; dry running is strictly prohibited.

Monitoring Indicators:

Oil temperature (≤80°C for standard seals, ≤150°C for high-temperature-resistant seals);

System pressure (≤25 bar).

Maintenance Requirements

Lubrication Management:

Regularly inspect and replace bearing grease (which is volatile).

Seal Inspection:

Check for radial seal wear during shutdown; replace if abnormal leakage is detected.

Storage Environment:

Store in a dry, corrosion-free location to prevent moisture damage.