Wenglor's P1PY21 and GM04 Sensors: Enhancing Optical Detection Reliability in Modern Factories

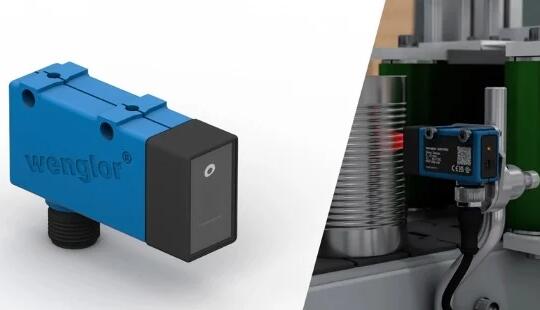

In the high - speed environment of factory production lines, precision has always been an indispensable requirement. However, glossy packaging materials, transparent adhesives, and red - hot metal surfaces often pose challenges to traditional sensors, causing errors, delays, and costly misreadings. For industries such as automotive, packaging, and food production, even a single detection failure can lead to significant production downtime or product defects. Engineers have been struggling for a long time to find sensors that can effectively handle complex and rapidly changing environments. Wenglor Sensoric Group is offering a two - part solution. The company has introduced two advanced sensors, each playing a crucial role in the complex detection process: the P1PY21 series, the world's first Time - of - Flight (ToF) sensor utilizing blue laser technology, and the GM04 gloss sensors, specifically designed for accurate differentiation between matte and glossy surfaces.

The World's First ToF Sensor with a Blue Laser for Dark, Reflective Objects

Blue Laser Precision

The P1PY21 sensor is Wenglor's response to the most challenging visual obstacles on the production line. Traditional red lasers or infrared sensors often malfunction when scanning reflective, dark, transparent, or even glowing surfaces. This is because they either penetrate too deeply or are affected by thermal interference.

In contrast, the P1PY21's blue laser operates at a wavelength of 445 nanometers (shorter than red light), allowing it to focus on surface - level details without being confused by reflections or heat. This feature is particularly useful for detecting variations on polished metals, reading labels on glossy plastics, or monitoring organic materials coated with ink or paint. One of its key features is the line - shaped laser spot. The vertical line of the laser enhances accuracy when detecting objects that are partially obscured or have irregular shapes. Additionally, dynamic jump detection enables it to identify height variations on surfaces, which is especially beneficial when inspecting uneven or perforated materials. The P1PY21 also comes with a high - contrast OLED display for on - device configuration and can be managed remotely via Bluetooth using Wenglor's weCon app, simplifying setup and diagnostics, especially when the sensor is in a hard - to - reach location.

With a detection range of up to five meters and non - contact speed measurement capabilities, the sensor can keep pace with the fastest conveyor systems. Moreover, thanks to its Laser Class 2 safety rating, it can be directly deployed in factories without the need for special training or protective equipment.

Gloss Detection, Refined

While the P1PY21 addresses reflection and depth issues, Wenglor's GM04 gloss sensor focuses on distinguishing between matte and shiny surfaces. This may seem like a minor difference, but in industries such as packaging and printing, the ability to detect a transparent label or confirm uniform glue coverage is crucial for quality control.

With its compact M - format design (57.3 × 27 × 16 mm), the GM04 can be easily integrated into tight production spaces. It has a working range of 5 to 40 millimeters and remains stable even when objects are vibrating or slightly moving, which can be a problem for some optical sensors. It uses a simple potentiometer for quick manual adjustments, while IO - Link connectivity provides a faster digital interface for seamless integration and data handling. Finally, the GM04's adjustment knobs and IO - Link interface strike a perfect balance between manual fine - tuning and smart data integration.

These features make the GM04 an outstanding sensor in the market and a versatile addition to any setup that requires inspecting gloss levels, verifying drying stages, or detecting the presence of adhesives.

With Improvement Comes Opportunity

Manufacturers have long been plagued by a variety of problems in optical detection, such as shiny surfaces, transparent labels, vibration, and dust. Wenglor is addressing these isolated issues with the simultaneous launch of the P1PY21 blue laser sensor and the GM04 gloss sensor, thereby pushing the boundaries of reliable detectability in modern factory settings.