Baumer Unveils Robust Digital Cam Switch Tailored for Hoists and Winches

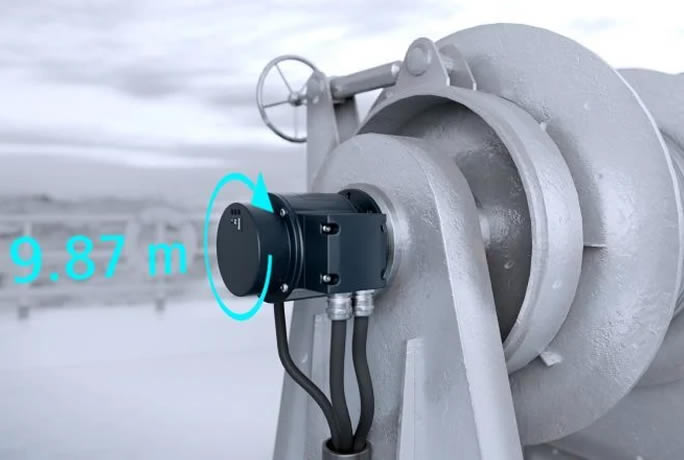

Baumer has introduced the PMG93 CAM, its latest digital cam switch crafted to streamline operations in demanding hoist and winch settings. To set up and configure the system, users simply require a laptop equipped with an Ethernet port and a web browser.

Baumer's subsidiary, Hüber Berlin—renowned for its encoders and tachogenerators—has engineered this innovative, user-friendly digital cam switch. The PMG93 CAM is built tough for heavy-duty use, offering straightforward installation and configuration to swiftly integrate hoist and winch systems.

Baumer Hüber Berlin’s HeavyDuty PMG93 Digital Cam Switch Simplifies Heavy-Duty Operations

Baumer Hüber Berlin’s HeavyDuty PMG93 digital cam switch is engineered to ease the complexity of heavy-duty hoist and winch operations. Image provided by Baumer.

Understanding Cam Switches

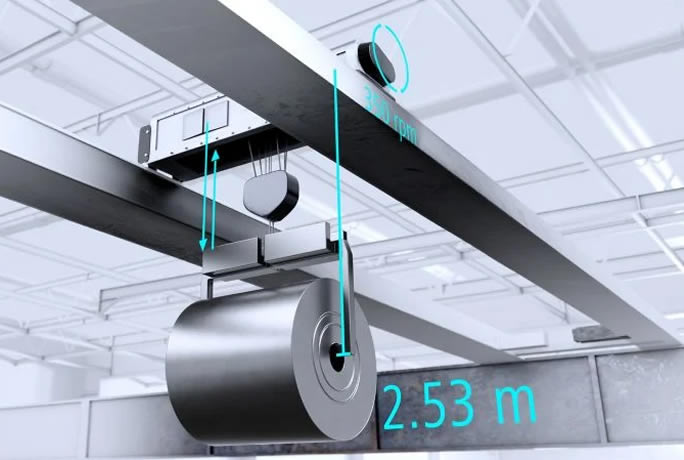

A cam switch operates through a rotating set of electrical contacts that can activate motors, pumps, or other machinery upon rotation. They facilitate the sequential startup of multiple devices, ensuring a proper and orderly initiation. Typically, cam switches are capable of handling high currents, making them ideal for crane and hoist controls.

Mechanical cam switches, however, are prone to wear and tear from heavy loads, vibrations, shocks, impacts, repeated motions, and corrosion. Programming them can also be complex, as it involves determining the length of cable, rope, or chain spooled or unspooled with each rotation.

PMG93 CAM: Simple Configuration with Basic Tools

Configuring the PMG93 CAM is a breeze, requiring only a laptop, an Ethernet connection, and a web browser. Image provided by Baumer.

Features of the PMG93 CAM Digital Cam Switch

The PMG93 CAM falls under Baumer’s “HeavyDuty” line, underscoring its durability in harsh, outdoor industrial settings. According to Baumer, the switch contains no mechanical components, rendering it virtually impervious to wear from vibrations and impacts.

A standout feature of the HeavyDuty PMG93 is its rapid and effortless configuration. System modifications can be implemented swiftly with minimal downtime. The PMG93 eliminates the need for proprietary software and specialized technician training; it can be programmed via a web browser interface and an Ethernet connection. It operates independently of software, relying solely on a browser interface, and does not require internet access—just an Ethernet cable and a laptop.

Each switch can be programmed using a “teach” mode, enabling technicians with minimal training to set up and operate the cam switch effectively. Its digital parameterization and diverse range of mounting kits mean that a single PMG93 can suffice for most applications, eliminating the need for multiple cam switches for different-sized hoists. It can be seamlessly integrated into new installations and used to upgrade and modernize existing equipment.

Retrofitting Capabilities

The PMG93 CAM can be used to upgrade existing systems, replacing traditional mechanical cam switches. Image provided by Baumer.

Heavy-Duty Application Suitability

Baumer Hüber Berlin designed the PMG93 ruggedized digital cam switch for use in challenging environments. Port facilities, which are subject to extreme temperatures, moisture, salt spray, and other environmental stressors, stand to gain significantly from the PMG93. Additionally, the oil and gas sector, metals processing for scrap and foundry operations, mining, and other outdoor materials handling applications are prime markets for the PMG93 CAM.