Core Structure and Materials

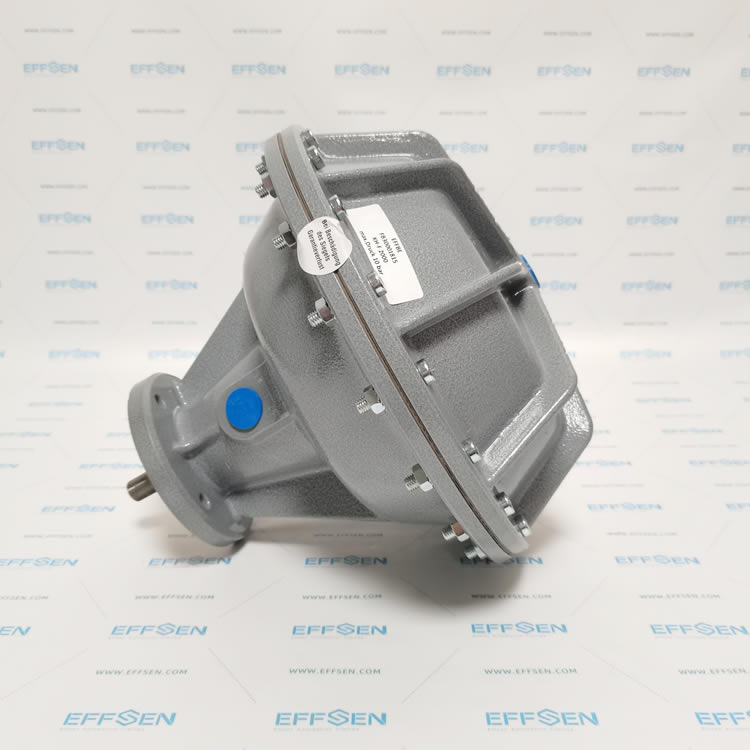

Three-part Housing Design: Flexibly adapts to customized customer interfaces, enhancing installation compatibility while ensuring long-term operational stability and reliability.

Drive Components: Made of surface carburized and hardened steel, offering strong wear resistance; composite material sliding bearings are equipped with a special coating, supporting dry running and featuring a long service life.

Sealing Options: Standard radial shaft seals are included, with derivative types such as slip ring seals available as options to accommodate different media and operating conditions.

Fluid Dynamics Optimization

Short Straight Flow Path Design: Reduces fluid resistance, achieving excellent suction performance and extremely low operating noise (<75 dB).

Special Tooth Profile Structure: Ensures high gear meshing accuracy, reduces internal leakage, and enhances volumetric efficiency (typical value >90%).

Industrial Applications:

Hydraulic Systems: High-pressure lubrication circuits for mining machinery, rolling mills, compressors, etc.

Power Equipment: Lubrication for diesel engines, cooling systems for steam turbines, and oil supply for wind turbine gearboxes.

Chemical Processes: Transporting media such as hot oil, heavy oil, emulsions, and polyethylene glycol.

Applicable Media Types:

Hydraulic oil, gear lubricants, diesel fuel, cutting oil, heavy oil, etc.

Compatible with media containing particulates (requires pre-filtration ≤25μm).