Founded in 1901 and headquartered in Kalamazoo, Michigan, Humphrey Products (USA) is a specialized manufacturer of pneumatic control components with over 120 years of history. Certified to ISO 9001 and ISO 13485 standards, the company sources 96% of its supply chain from within the United States, ensuring product consistency and reliability. Its solenoid valves are renowned for their high precision, long service life, and modular design, with widespread applications in industrial automation, medical equipment, and advanced manufacturing sectors.

Core Design Features

Structural Optimization

Compact Valve Body: Measuring approximately 2.38 × 0.75 × 1.25 inches (H × w × d), the aluminum alloy + brass construction weighs only 4 ounces (~113 grams), making it ideal for space-constrained applications.

Bistable Sealing: A combination of fluororubber (FKM) valve seats and stainless steel valve cores ensures a leakage rate ≤ 0.0005 SCFM (standard conditions), guaranteeing long-term sealing performance.

Low-Power Coil: Featuring copper wire windings and epoxy resin encapsulation, the coil maintains a temperature rise ≤ 25°C at a 40°C ambient temperature, supporting high-frequency switching up to 600 cycles per minute.

Functional Innovation

Manual Emergency Operation: Certain models are equipped with top push rods, enabling forced valve position switching during power outages (e.g., for maintenance and debugging).

Wide Pressure Adaptability: Stable control is maintained across the full range from vacuum (-28" Hg) to 125 PSI, eliminating the need for additional pressure boosters.

Typical Application Scenarios

Industrial Automation

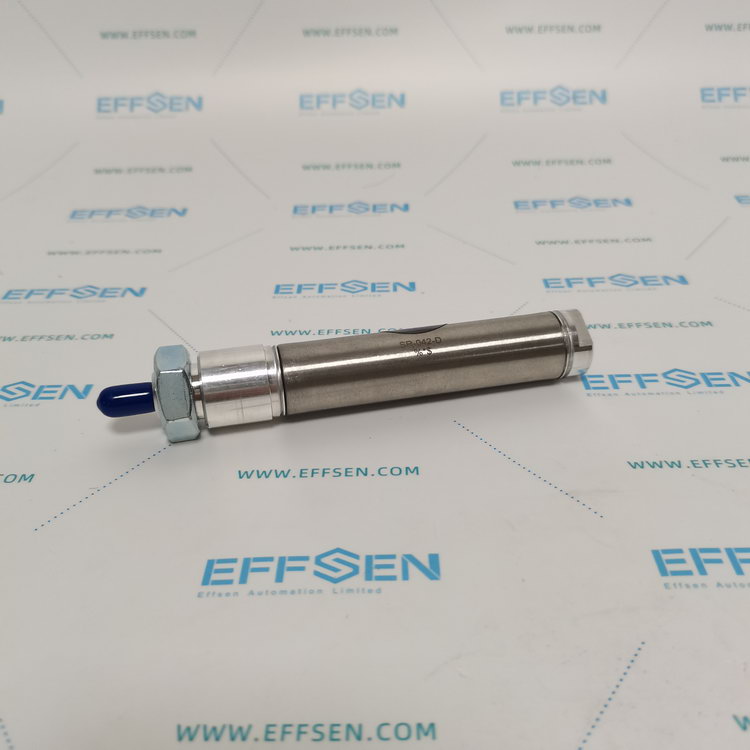

Pneumatic cylinder actuation in production lines (e.g., assembly line positioning, gripper control), compatible with standard actuators from SMC/Festo.

Medical Equipment

Gas pathway switching in ventilators, meeting ISO 13485 medical-grade cleanliness requirements (custom copper-free valve bodies available).

Packaging Machinery

Material metering and filling systems, achieving ±1% precision adjustment with a Cv of 0.17 flow rate.

Environmental Control

Inert gas protection systems (e.g., welding equipment), resistant to non-corrosive media such as argon and nitrogen.

Installation and Maintenance Specifications

Pipeline Preparation: Purify the air supply using a 5-micron filter and apply Loctite 545 sealant to threaded connections.

Electrical Safety: Install a freewheeling diode (e.g., 1N4007) to protect the coil and ensure grounding resistance < 10Ω.

Service Life Maintenance:

Replace the main seal kit (part number: 310-SK01) every 5 million cycles.

Calibrate pressure response every 2 years.