Humphrey (USA) is an internationally renowned supplier of pneumatic equipment, renowned for its solenoid valves featuring high response speed, low power consumption design, and modular construction. Specifically optimized for industrial automation pneumatic control systems, these valves are ideal for high-frequency applications such as robotics and packaging machinery.

Core Design Features

Valve Body Structure and Functionality

5/2 (Two-Position, Five-Port) Design: Equipped with five ports (1 pressure inlet P, 2 working ports A/B, and 2 exhaust ports R/S), enabling precise bidirectional control of double-acting cylinders. The spool displacement response time is <15 ms (energized) / 10 ms (de-energized).

Dual-Coil Bistable Structure: The dual-electrically controlled coils (model code "E2") support pulse excitation (requiring only 100 ms of energization). After de-energization, magnetic force maintains the spool position, with power consumption as low as 4.8 W (Class F insulation).

NAMUR Interface Standard: Compliant with ISO 5599/1 installation specifications, allowing direct mounting on cylinders or integrated valve manifolds to save piping space.

Durability and Intelligence

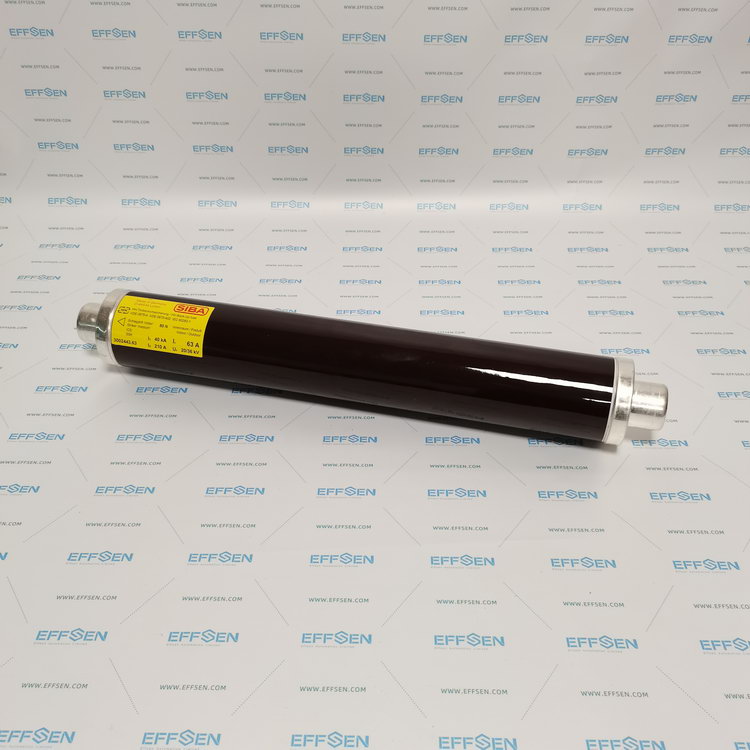

Full-Flow Valve Body: Featuring a 1/4" port size (Cv value ≥ 1.8) and a pressure drop <1 PSI (@60 PSI), it supports high-flow gas transmission (inert gases/compressed air).

Dual-Color LED Status Indicator: Red/green indicators provide real-time display of valve operating positions, facilitating rapid fault diagnosis.

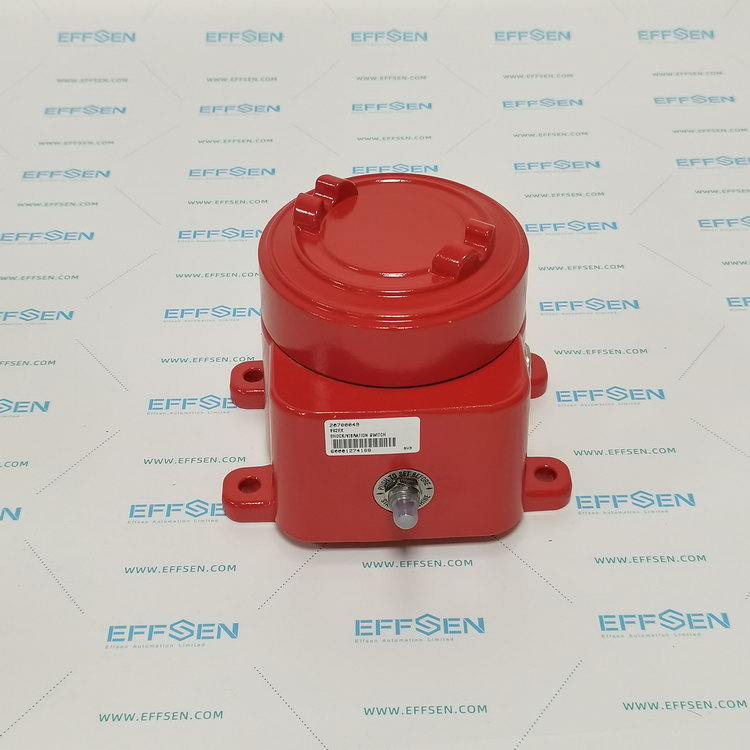

Manual Emergency Override Lever: A top push-pull mechanical override function enables forced valve position switching during power outages, ensuring system safety.

Typical Application Scenarios

Industrial Automation

Robot Gripper Control: High-frequency grasping (>900 CPM) with cylinder stroke accuracy of ±0.5 mm, used for positioning in automotive assembly lines.

Packaging Machinery: Gas circuit switching for film sealing and filling valve groups, withstanding vibration and shock (EN 60068-2-6 standard).

Specialized Equipment

Semiconductor Vacuum Chambers: Rapid switching of inert gases (e.g., nitrogen) with a leakage rate <0.1 mL/min (@8 bar).

Injection Molding Machine Ejection Systems: Linked with SQE2 quick exhaust valves to reduce mold opening cycle time by 30%.