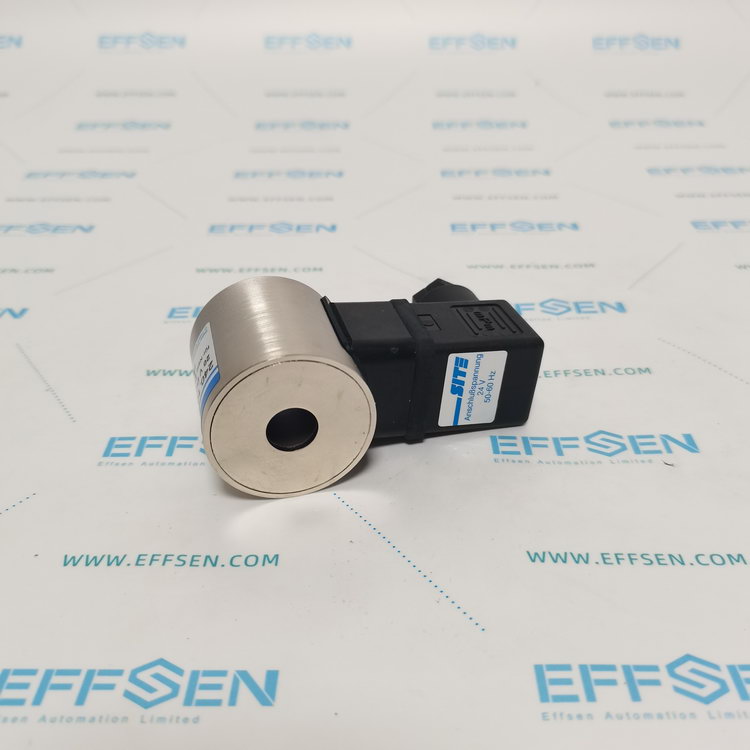

The Hydrotechnik 2103-40-22.00N is a high-precision Minimess® series pressure measuring connector manufactured in Germany, specifically designed for hydraulic systems and high-pressure fluid testing scenarios. It is renowned for its rapid sealing connection and precise pressure measurement capabilities.

Product Overview

The Hydrotechnik 2103-40-22.00N is a Minimess® ball-sealing pressure measuring connector produced by Hydrotechnik GmbH in Germany. Featuring a quick-plug design, it enables leak-free connections in high-pressure environments and is widely used for pressure detection and fault diagnosis in hydraulic systems, construction machinery, energy equipment, and other fields. This product inherits the Minimess® technology invented by Hydrotechnik in 1964, becoming a key component in industrial pressure measurement due to its high reliability, reusability, and compatibility.

Technical Specifications

Parameter Category Specification Description

Model 2103-40-22.00N

Brand/Origin Hydrotechnik / Germany

Connection Thread Type Inferred as G1/4 or M14x1.5 based on model identification (subject to actual marking)

Maximum Operating Pressure 63 MPa (630 bar)

Sealing Material Standard configuration: NBR (Nitrile Butadiene Rubber); Optional: FKM (Fluororubber) for high-temperature or corrosive media

Temperature Range -30℃ ~ +120℃ (NBR) / -20℃ ~ +200℃ (FKM)

Main Body Material Steel 1.0718 (zinc-nickel plated for rust prevention); Optional: Stainless Steel 1.4571

Connection Type Quick-plug ball-sealing structure

Applicable Media Hydraulic oil, mineral oil, water-based liquids, gases (selection based on sealing material)

Design Features

Rapid Leak-Free Connection:

The unique ball-sealing structure allows for safe connection and disconnection under system pressure without shutdown, significantly improving detection efficiency.

High Precision and Repeatability:

Maintains stable sealing performance after multiple uses, ensuring accurate and reliable pressure data while reducing measurement errors.

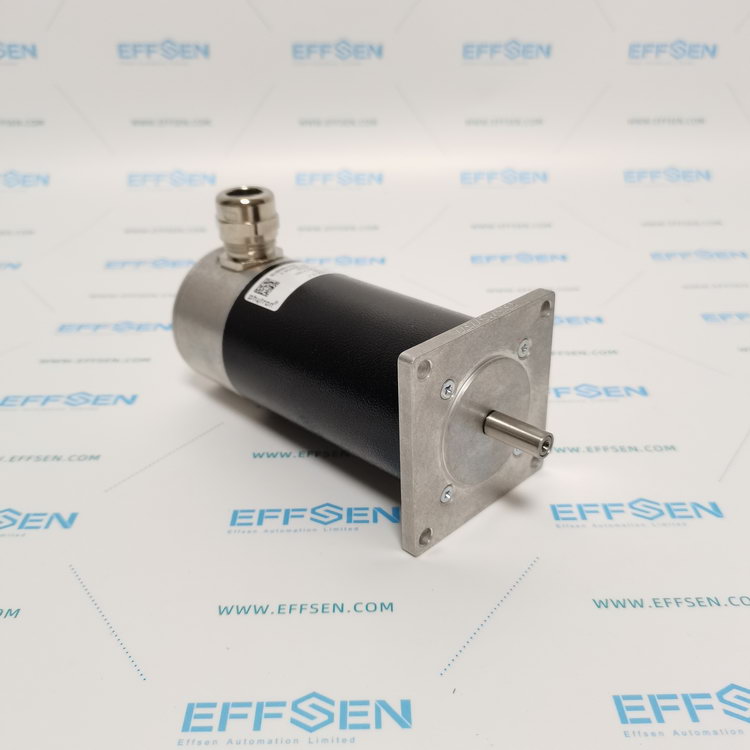

Robust and Durable:

The main body is made of high-strength steel or stainless steel, resistant to corrosion and vibration, suitable for harsh industrial environments.

Wide Compatibility:

Offers various thread specifications (e.g., G1/4, G3/8, NPT, UNF, etc.), compatible with the majority of hydraulic test instruments, sensors, and hose interfaces.

Application Areas

Construction Machinery: Pressure monitoring and fault diagnosis in hydraulic systems of excavators, loaders, etc.

Energy and Power: High-pressure fluid testing and equipment maintenance in the oil and power industries.

Automotive Manufacturing: Brake system and transmission hydraulic test benches.

Industrial Automation: Performance verification and quality control of hydraulic components on production lines.