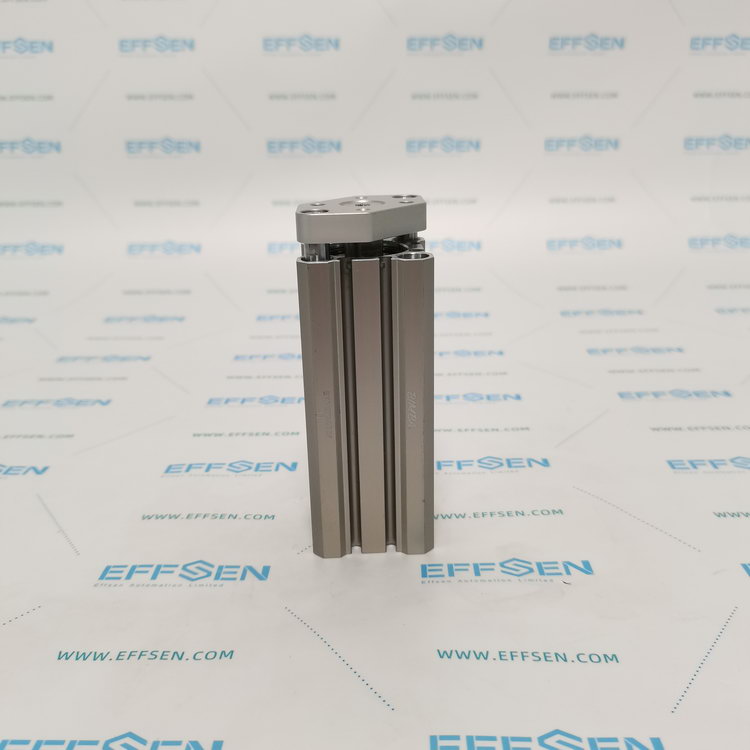

Humphrey, as a professional brand in the field of pneumatic components (affiliated with SMC Group in the United States), distinguishes its double-rod cylinders with core advantages such as high rigidity, synchronous precision, and resistance to eccentric loads, making them suitable for precision positioning and high-stability industrial applications. The HTBDAM series employs a dual-piston rod symmetrical structure, significantly enhancing torsional stiffness and motion stability.

Core Design Features

Double-Rod Symmetrical Reinforced Structure

Improved Eccentric Load Resistance: The parallel arrangement of dual piston rods (rod diameter φ4mm) increases lateral rigidity by over 50% compared to single-rod cylinders, enabling them to withstand a maximum lateral force of ≥120N (@0.6MPa operating conditions) and effectively suppressing bending deformation of the piston rods.

Optimized Synchronous Precision: The mechanically coupled design of the dual rods ensures an axial displacement deviation of ≤±0.1mm, making them suitable for precision gripping and alignment tasks (e.g., positioning platforms in semiconductor equipment).

High-Performance Sealing System

Low-Temperature Adaptability: The use of fluororubber (FKM) primary seals supports operation across a wide temperature range from -10°C to +100°C, maintaining elasticity even in frozen food packaging lines (-25°C environment).

Low-Friction Design: Preloaded PTFE wear rings enable a starting pressure of ≤0.05MPa, reducing low-speed crawling phenomena and facilitating precise speed control scenarios.

Modular Functional Expansion

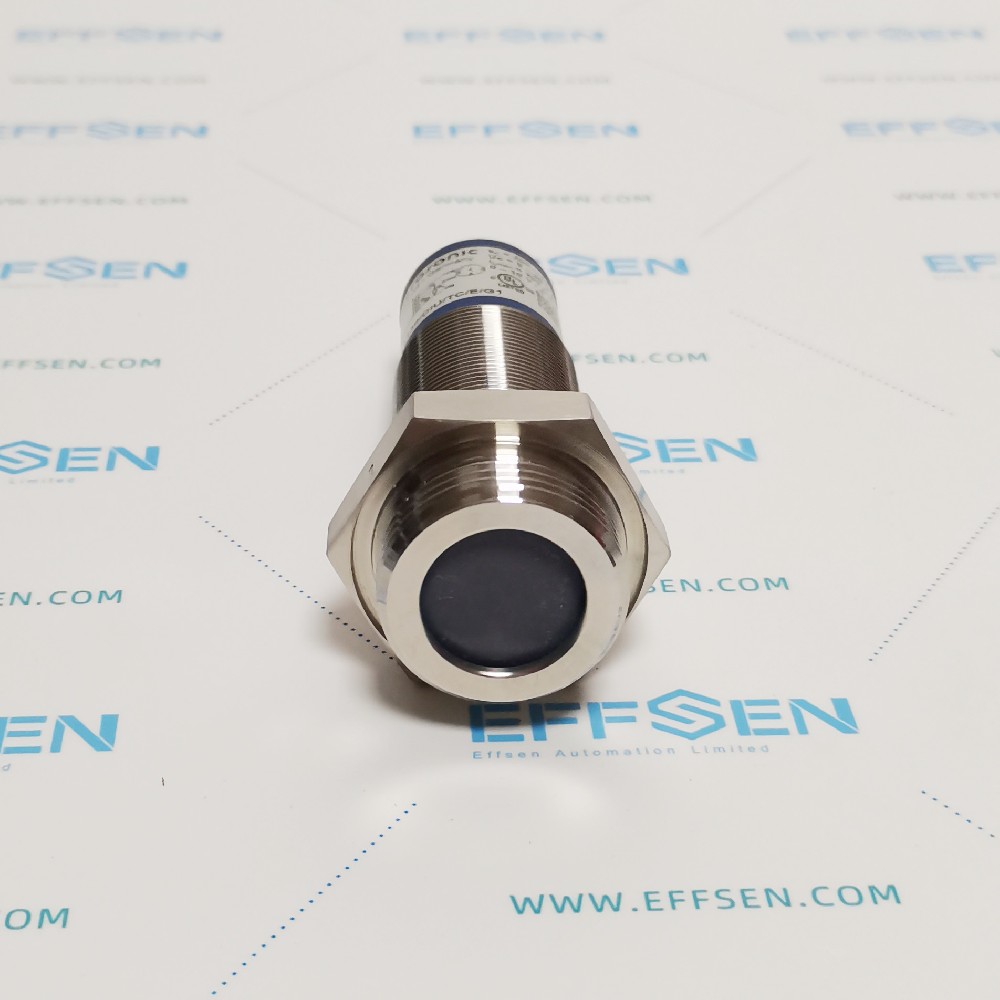

Multi-Sided Sensor Slots: Three sides of the cylinder barrel are equipped with magnetic switch slots (compatible with φ4mm magnetic rings), supporting flush installation and providing position feedback accuracy of ±0.5mm.

Adjustable Buffering Mechanism: Bidirectional pneumatic buffers (adjustable over the final 20mm of stroke) limit impact acceleration to ≤10g, extending service life to ≥3 million cycles.

Typical Application Scenarios

Precision Manufacturing Equipment

CNC Machine Tool Tool Magazine Change Mechanism: Dual-rod synchronous drive ensures tool shank positioning errors of ≤0.1mm, withstanding cutting fluid splashing environments (IP67 protection rating).

Electronic Component Placement Machine Nozzle Platform: Low-friction characteristics enable uniform motion at 50mm/s, preventing component misalignment.

Heavy-Duty Material Handling

Automobile Welding Fixture Synchronous Locking: Dual cylinders in parallel deliver an output force of ≥350N, resisting positioning failures caused by welding vibrations.

Injection Molding Machine Ejection Mechanism: High-temperature-resistant seals accommodate 120°C thermal radiation from the mold surface, achieving 500,000 cycles without leakage.

Harsh Environment Systems

Food-Grade Stainless Steel Variant (Optional): FDA-certified for use in dairy filling line valve actuation, withstanding pH 2-12 cleaning agents.

Ship Deck Machinery: Salt spray test endurance of ≥1,000 hours, paired with a seawater lubrication system (custom non-ferrous materials required).