Rickmeier Gear Pump R46/180 FL-Z-W-SAE3-R

Core Power for High-Precision Heavy-Duty Lubrication Systems

The R46/180 FL-Z-W-SAE3-R is a flange-mounted external gear pump designed by Germany's Rickmeier for demanding industrial applications, specializing in the long-life, stable delivery of high-viscosity media (such as lubricating oils, hydraulic oils, and synthetic oils). Its modular design complies with DIN/SAE standard interfaces, making it an ideal choice for lubrication systems in compressors, gearboxes, and large engines.

Key Performance and Technical Advantages

Adaptability to Heavy-Duty Conditions

Pressure Range: Continuous operating pressure of 25 bar (peak pressure of 30 bar), suitable for high-pressure lubrication pipeline systems.

Viscosity Compatibility: Supports media with a kinematic viscosity of 10~2,000 mm²/s (including oils with EP extreme pressure additives).

Temperature Range: -30°C to +120°C (with upgraded seal temperature resistance up to +150°C).

Long-Lasting and Reliable Design

Hardened Gears: Nitrided gear set (hardness ≥900 HV) with a 40% increase in wear resistance life.

Side Plate Compensation: Automatic pressure-compensating side plate design reduces internal leakage and maintains high-pressure efficiency.

Bearing Load: Optimized bearing support structure with enhanced axial/radial load-bearing capacity, eliminating the risk of stalling.

Industrial-Grade Integration and Convenience

Standard Interface: SAE 3 flange seamlessly fits DIN 24550 pipeline systems, reducing modification costs.

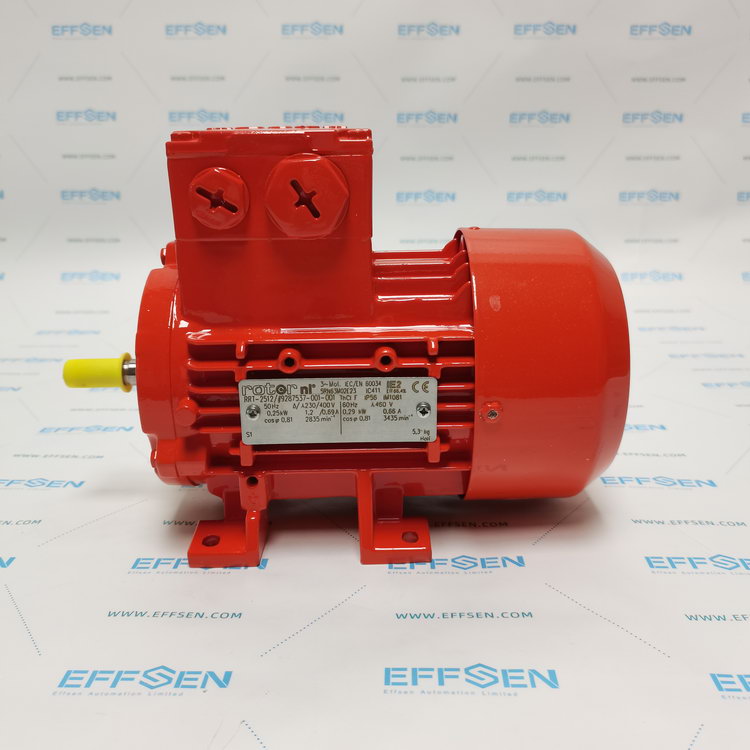

Drive Compatibility: Through-shaft design supports tandem pump units and can be equipped with flexible couplings/direct-connected motors (IEC B5/B14).

Maintenance-Friendly: Removable front cover structure allows for seal replacement without disassembling pipelines.