Product Overview and Technical Features

Core Functions

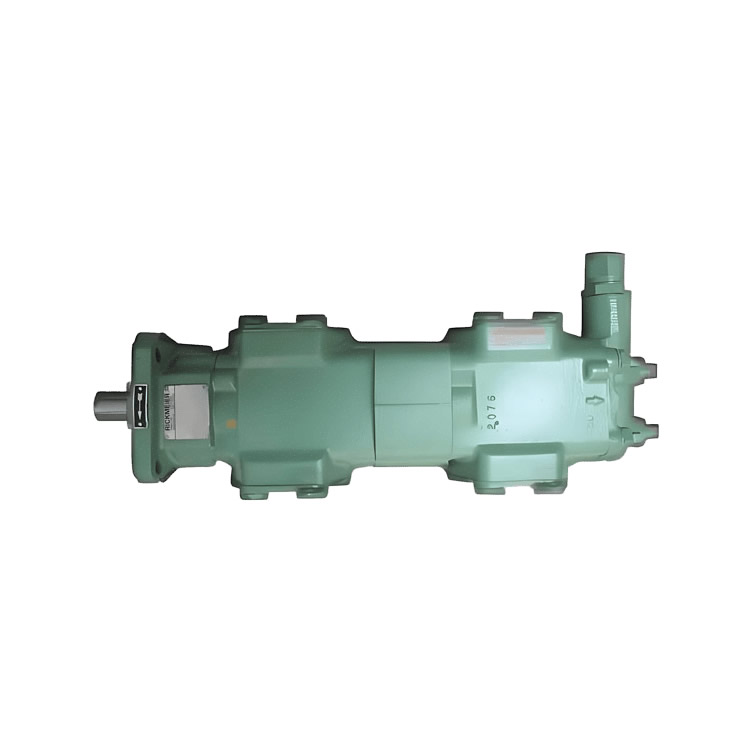

Specifically designed for delivering lubricating oil or fuel to large engines, gear systems, and transmission units, applicable in fields such as marine, energy, and heavy industry.

Adopts a modular system that supports customized interfaces to meet specific customer requirements.

Performance Advantages

Highly Efficient Self-Priming: No pre-filling of liquid is required before startup; the pump is automatically lubricated by the conveyed medium, reducing maintenance costs.

Low-Noise Operation: Special tooth profile structures combined with short straight fluid channels significantly reduce operational noise.

Dry Running Tolerance: Composite-coated sliding bearings (Type P10/DU) support short-term dry running (≤20 minutes), provided conditions such as the absence of radial forces and balanced inlet/outlet pressures are met.

Structural Design

Three-Part Housing (Gray Cast Iron EN-GJL-250): Facilitates easy adaptation to customer interfaces and straightforward maintenance.

Hardened Drive Components: Surface-carburized steel (16MnCrS5) gear shafts offer high wear and fatigue resistance.

Sealing Options:

Standard radial shaft seals (NBR/FKM materials) with a temperature resistance of ≤80℃;

Optional mechanical seals with a pressure resistance of up to 25 bar, suitable for high-temperature operating conditions (requiring supporting components such as heat-resistant couplings).

Structural and Material Design

Bearing System: Large-sized composite sliding bearings with special coatings enhance dry running lifespan.

Corrosion Protection: Two-component RAL 6011 paint coating.

Shaft Seal Protection:

Standard radial shaft seals withstand pressures up to 6 bar, while mechanical seal versions withstand pressures up to 25 bar.

Rotation Direction: The default rotation direction is clockwise (viewed from the drive shaft end); the optional Type C version allows for bidirectional rotation (requires the absence of a pressure relief valve).