Product Overview and Core Features

Functional Positioning

Lubrication and Hydraulic Transmission: Specifically designed for delivering lubricating oil or hydraulic oil to industrial equipment (such as gearboxes, bearings, and hydraulic systems), suitable for high-viscosity media (5–20,000 mm²/s).

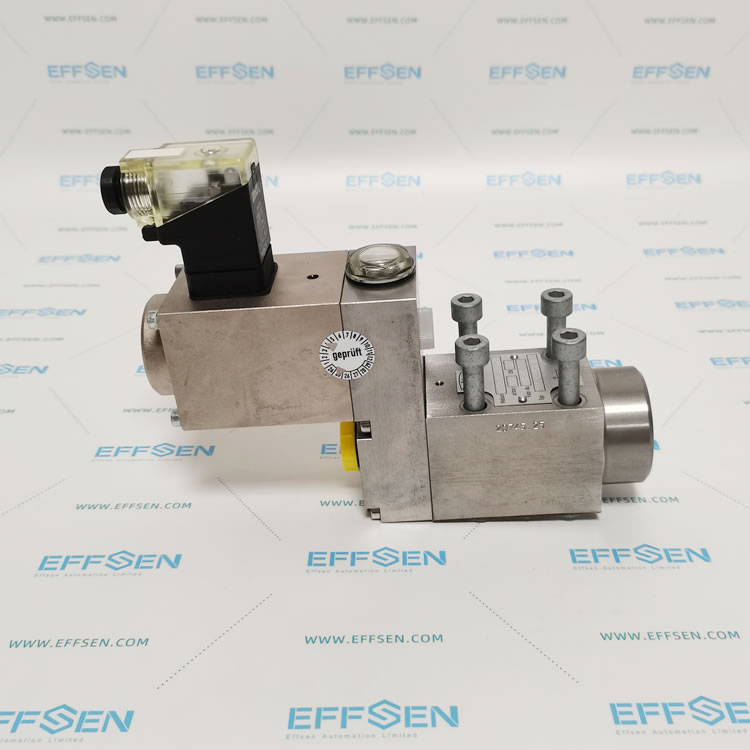

Modular Design: Supports customized interfaces (e.g., SAE flanges, integration of DB pressure control valves) to meet complex system integration requirements.

Performance Advantages

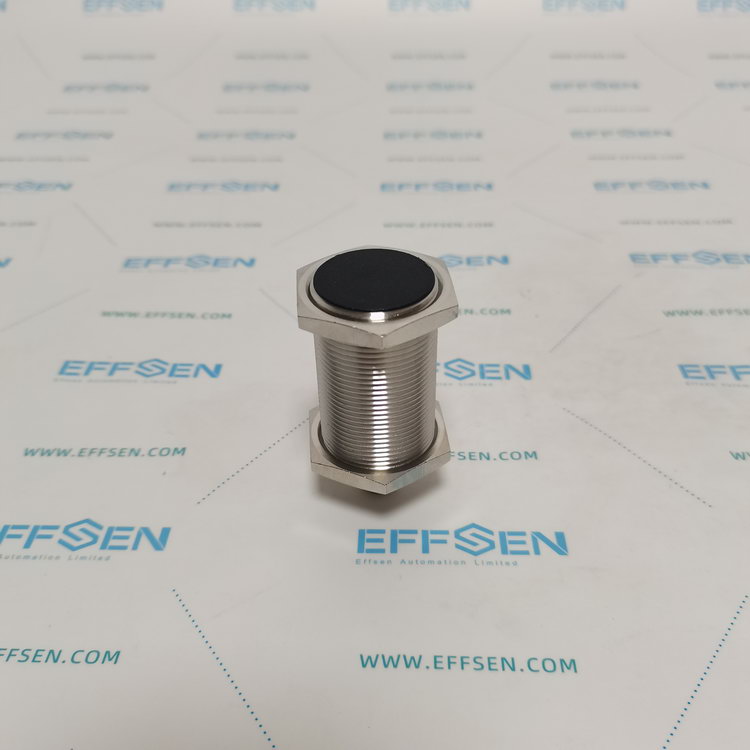

High Pressure Resistance: The maximum operating pressure reaches 25 bar (continuous pressure recommended ≤15 bar), meeting the power demands of heavy-duty machinery.

Wide Viscosity Adaptability: Compatible with mineral oils, synthetic oils, bio-oils, etc., with a viscosity range covering 5–20,000 mm²/s.

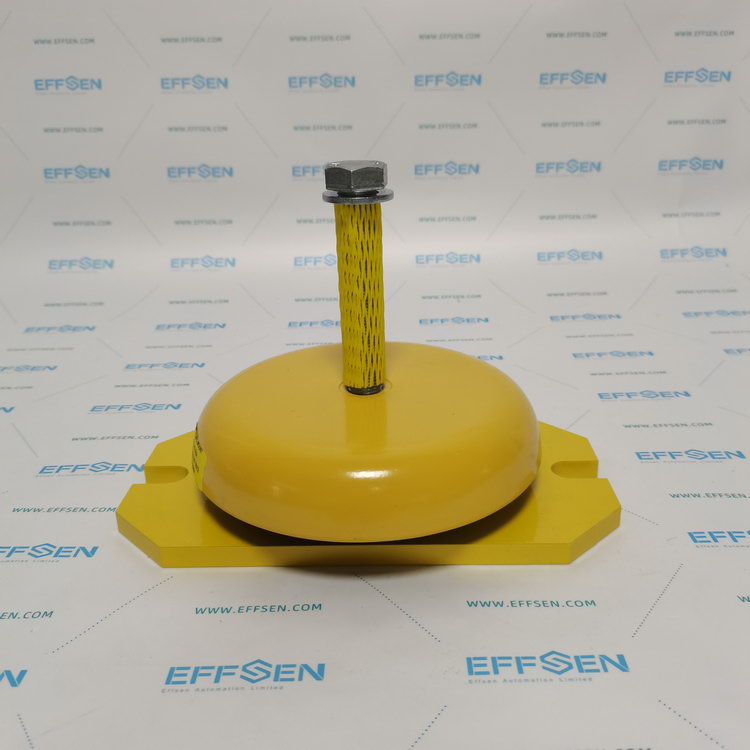

Low Maintenance Design: Features no vulnerable seals, and composite-coated sliding bearings support short-term dry running (≤20 minutes), reducing downtime risks.

Structural Details

Materials and Sealing:

Housing: Gray cast iron (EN-GJL-250) with a two-component anti-corrosion coating.

Bearings: Composite sliding bearings (P10/DU coating) resistant to dry running impacts.

Seals: Standard radial shaft seals (NBR), with optional FKM or mechanical seals available.

Typical Application Areas

Industrial Hydraulic Systems: Power units for injection molding machines, presses, and lifting equipment.

Mobile Machinery: Steering/braking systems for engineering vehicles and hydraulic drives for ship steering gears.

Energy Equipment: Turbine lubrication for generator sets and cooling oil circulation for compressors.

Harsh Environments: High-temperature, high-load scenarios such as mining machinery and metallurgical rolling mills.