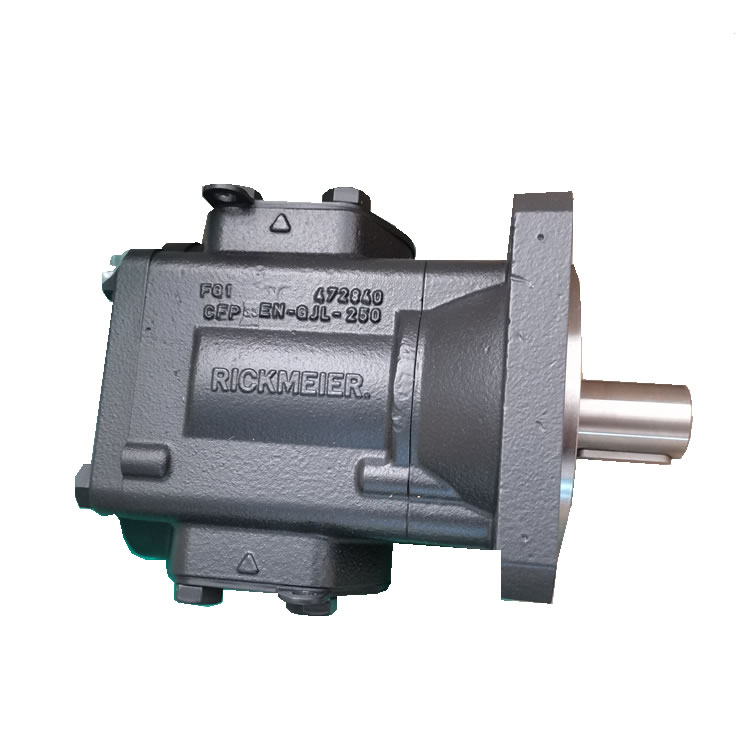

The Rickmeier R65 series gear pumps are industrial-grade power components specifically designed for the conveyance of high-pressure and high-viscosity media. They are widely applied in hydraulic systems, lubricant transfer, fuel supply, chemical processes, and heavy-duty mechanical equipment. This model meets demanding operational requirements through modular combinations, offering three core advantages: reliability, energy efficiency, and long service life.

Efficient Fluid Conveyance

Displacement Range: 80~350 cm³/rev

Viscosity Adaptability: 10~1000 cSt (supports ISO VG 32~680 grade lubricants/hydraulic oils)

Volumetric Efficiency: ≥95% (@100 bar, 1500 rpm)

Robust Structure and Materials

Housing: EN-GJL-250 gray cast iron, pressure-resistant and impact-resistant

Gears: 20MnCr5 carburized and quenched gears (hardness 60±2 HRC), precision ground teeth (DIN 3962 Class 6)

Bearings: Copper alloy plain bearings with built-in pressure balancing grooves to reduce lateral loads

Low-Noise and Low-Pulsation Design

Optimized tooth profile + axial compensation technology, with pressure pulsation ≤ ±1.5%

Operating noise ≤ 75 dB(A) @ 1500 rpm (typical value)

Broad Media Compatibility

Applicable Media: Hydraulic oils, gear oils, bio-based oils, fuels (DIN EN 590), synthetic esters

Operating Temperature: -30°C ~ +120°C (limited by seal material tolerance)