Performance Parameters

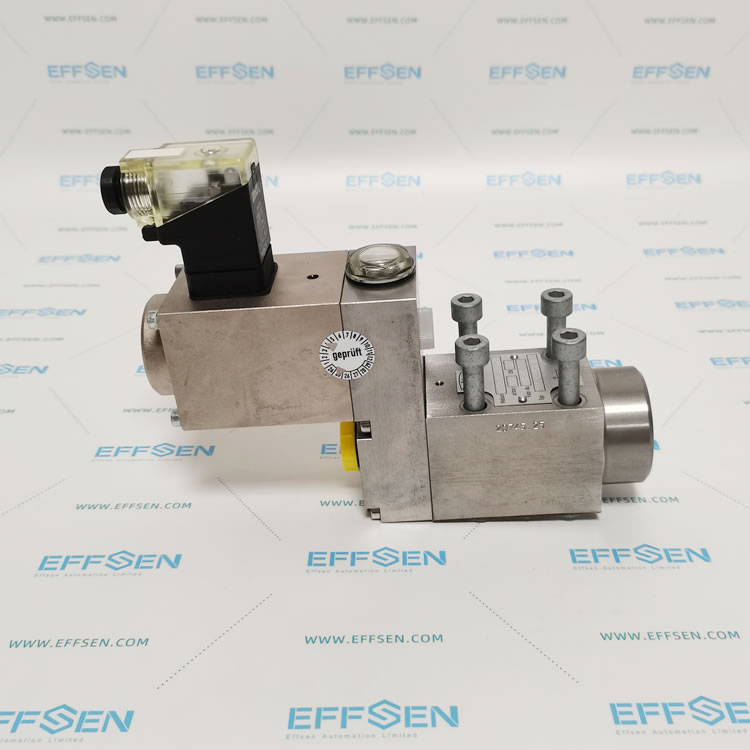

Maximum Operating Pressure: 300 bar (under continuous operating conditions), with a peak pressure of up to 350 bar.

Viscosity Range: Suitable for media with a viscosity of 10–1500 cSt (such as hot melt adhesives, resins, asphalt, lubricants).

Temperature Range: -30°C to +180°C (upper limit determined by sealing materials).

Rotational Speed Range: 100–1350 rpm (recommended rotational speed of 500–1000 rpm to optimize service life). Applications include polymer extrusion production lines (such as pelletizers and reactor feed systems).

High-temperature asphalt/heavy oil transfer systems.

Metered transfer of high-viscosity resins and plasticizers in chemical processes.

Centralized lubrication systems for large equipment (such as wind turbine gearboxes and rolling mills).

Inapplicable Scenarios:

Media containing solid particles or highly corrosive substances (custom hardening treatment required).

Precision metering applications requiring extremely low pulsation (screw pumps are recommended).

III. Technical Advantages

High-Pressure Durability

Utilizes hardened gears and floating bushing design, which automatically compensates for clearance after wear, maintaining high volumetric efficiency (>90%).

Low-Shear Transfer

Optimized involute gear tooth profiles reduce structural damage to sensitive media (such as hot melt adhesives).

Modular Configuration

Seal Options: Replaceable with high-temperature/corrosion-resistant seals such as V (Viton fluororubber) and G (graphite packing).

Drive End Adaptability: Available with SAE, DIN, or ISO standard flanges (this model features a DIN flange).